Harley-Davidson took a punt when it launched its Street models last year—and it’s paid off. The Street 750 and 500 are doing especially well in international markets, where there’s less emphasis on cubic inches.

In Europe, Harley is stoking the fires with its Battle of The Kings competition, pitching dealers against each other in a custom bike build-off. This is one of our favorites—built by Austrians Fabian Weber and Gregor Malleier of H-D Innsbruck.

The Harley Street 750 is what you might call an ‘accessible’ bike—in both financial and riding terms. So the builders have to get maximum bang for the buck, spending no more than €4,000 on parts and keeping the workshop hours down to 50 or less.

Despite those restrictions, Fabian and Gregor have built a very stylish machine indeed. Workshop manager Gregor used to be a racebike mechanic, and can also build his own frames—so he knows how to work quickly.

His protégé Fabian brings enthusiasm as well as automotive skills, and is a convert to the new wave custom scene: “Before we started the project, I was on holiday in Cape Town, South Africa. I came back inspired by the cafe racer scene,” he says. “I was even more pleased when Gregor assigned the main part of the project to me, such as design and selection of parts!”

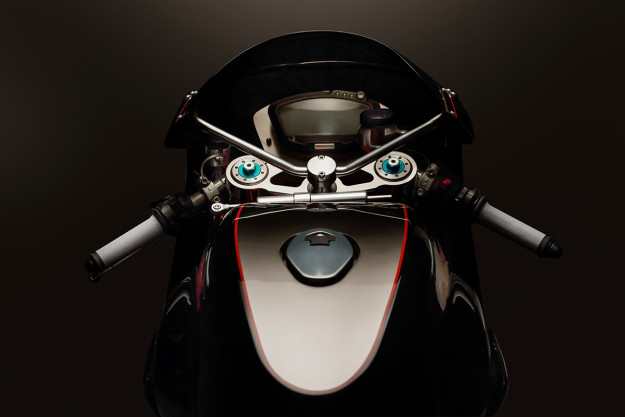

The modifications are well chosen for maximum impact. Fitting a Free Spirits triple tree up front has increased the visual weight of the forks, which lose the stock rubber gaiters. Fabian has also lowered the forks and fitted a 19-inch Dyna front wheel, two inches larger than stock.

The new triples have also allowed the speedo to be hidden better and the fairing repositioned for better lines. Free Spirits clip-ons increase the café racer vibe.

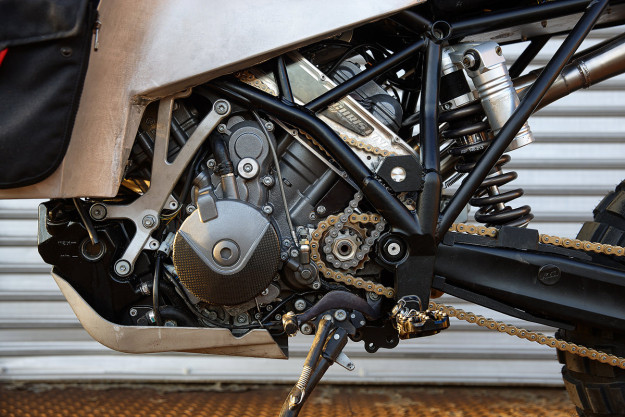

The rear wheel has gone up two inches in size too: it’s a 17-inch item from the Softail Cross Bones model. After a little drilling and re-arrangement, the Street 750 pulley was able to fit. The rear fender was widened and shortened to match, and a discreet LED strip fitted for lighting.

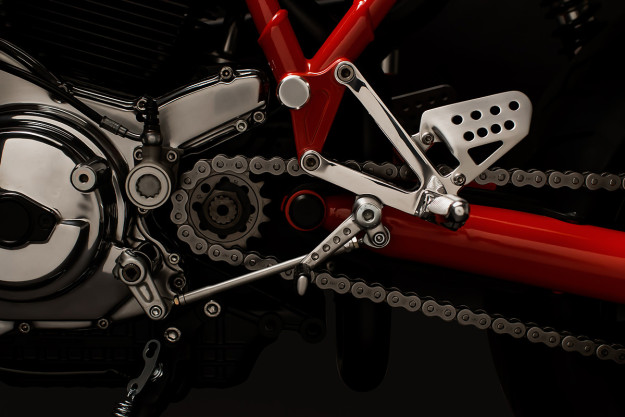

There’s a custom saddle on top of the standard seat pan, and the ignition lock and horn have been moved to clean up the overall look. The wiring harness, traditionally a bugbear of lower-cost bikes, has been partially hidden. The mid controls have been drilled and powder coated, and drilled H-D ‘Silencer’ footpegs installed.

The exhaust headers are standard, but the look of the system has been transformed by fitting a stubby, screw-mountable muffler—which can be returned easily to stock.

It shows what can be done with a little ingenuity, and not too much cash. And if this is the future of Harley-Davidson customizing, we’re all for it.

You can examine the other Harley Street 750 builds in the Battle Of The Kings competition here—we’ve already covered the XRTT Racer from Belgium. The finale of the competition will be next month at the Wheels & Waves Festival in Biarritz, France, where a panel of judges will pick a winner.

I’m betting this one has a very good chance indeed.

Battle Of The Kings | H-D Benelux Facebook | Harley-Davidson Innsbruck | Images by Christoph Villgrattner